Badania

Dalsza część opinii

O efektach produkcji pod osłonami decydują czynniki biologiczne oraz techniczne. Czynniki techniczne pełnią rolę służebną czyli ich odziaływanie i nastawy winny umożliwiać wzrost, plonowanie i wysoką jakość uprawianych roślin. Konstrukcja szklarni, techniczne wyposażenie obiektu oraz mikroklimat decydują o efektach produkcyjnych i ekonomicznych. Jak podaje Stachowiak (2009) w procesie sterowania mikroklimatem należy mieć na uwadze zarówno względy produkcyjne jak też nakłady energetyczne, których udział sięga 40 aż 50 % (Rutkowski). Temperatura, wilgotność, światło oraz skład powietrza w układzie przestrzennym szklarni winny spełniać wymagania uprawianych roślin. Rodzaj elementów grzejnych, ich rozmieszczenie oraz sterowanie mają zasadniczy wpływ na mikroklimat.

Dalsza część opinii

Elementy grzejne nowej generacji

W ostatnich latach coraz więcej uwagi poświęcamy zagadnieniom związanych z mikroklimatem. Temperatura, wilgotność, skład powietrza to czynniki, które nie tylko decydują o efekcie produkcyjnym czyli ilości i jakości uzyskiwanego plonu ale także mają istotny wpływ na wielkość nakładów energetycznych czyli zapotrzebowanie ciepła.

Przed kilkoma laty pojawiły się na rynku rury grzewcze stalowe o przekroju gwiazdy (tzw. rury Walczaka). Okazało się, że efekty są imponujące. Kilkukrotne zmniejszenie pojemności przedmiotowych rur pozwala na szybkie dopasowanie wydajności grzewczej rur do zmiennych warunków otoczenia. Cecha ta eliminuje w dużej mierze przegrzewanie szklarni i pozwala na uzyskanie znacznych oszczędności w ilości dostarczanego do szklarni ciepła. Ciekawostką nowej generacji rur jest to, że grzejniki te mają zróżnicowaną temperaturę na powierzchni. Cecha ta umożliwia zmianę formy przekazywania ciepła. Nie jest obojętne, czy ciepło przekazywane jest z wykorzystaniem zjawiska konwekcji czy radiacji. Ciepło dostarczane w formie radiacji (co występuje przy wyższej temperaturze) pozwala na uzyskanie wyższej temperatury roślin w stosunku do otoczenia. Efekt ten ogranicza występowanie punktu rosy na uprawianych roślinach, a tym samym poprawia asymilację oraz znacznie ogranicza występowanie chorób grzybowych. Śledząc produkcję w której stosuje się rury Walczaka wyraźnie widoczne są wielokierunkowe efekty. Głoszone referaty oraz publikacje dotyczące rur Walczaka zarówno w kraju oraz poza jego granicami cieszyły i cieszą się ogromnym zainteresowaniem. Z ogromną przyjemnością prowadzi się badania i przekazuje się zdobytą wiedzę kiedy efekty zastosowanych rozwiązań są wysoce pozytywne (Rutkowski, Knaga 2015).

Obecnie produkowane są rury podobnie jak wyżej wymienione o przekroju gwiazdy ale tym razem wykonane z tworzyw sztucznych (polipropylenu oraz polietylenu). Skąd ten pomysł? Wystające elementy nowej generacji grzejnika (ramiona gwiazdy) podobnie jak przy stalowych mają niższą temperaturę w stosunku do zagłębień. Roślina przy ogrzewaniu wegetacyjnym styka się z chłodniejszą częścią elementu grzejnego, stąd miejsce kontaktu nie stanowi zagrożenia poparzeniem. Dlatego z powodzeniem tego rodzaju elementy grzejne można stosować do ogrzewania wegetacyjnego. Zagłębienia rur pozwalają na przekazywanie energii o wyższej temperaturze, która korzystnie wpływa na ich rozwój. Przewody z tworzyw sztucznych nie korodują, posiadają mniejsze opory przepływu cyrkulującej cieczy a ujemną stroną przedmiotowych rur jest to, że wymagana jest większa ilość zawieszek podczas umieszczania ich w strefie wegetacji roślin. Nasuwa się pytanie czy objęte badaniami przewody mają służyć tylko do ogrzewania szklarni? Chyba nie tylko, albowiem niektóre cechy predysponują zastosowanie ich do innych celów. Przyjęty kształt gwiazdy umożliwia stosowanie ich do ogrzewania roślin w uprawach polowych podczas ukorzeniania, albowiem wykazują one większą odporność na uszkodzenia spowodowane niskimi temperaturami. Posiadana wiedza oraz kontakty z firmami zagranicznymi pozwalają twierdzić, że zapewnie wykorzystane one będą nie tylko w szklarniach. Przecież nasi sąsiedzi z Czeskiej Republiki cieszą się uznaniem z produkcji wymienników ciepła w których elementy wymiany ciepła wykonane z tworzyw sztucznych i spełniają swoją funkcję przy równoczesnej kilku aż kilkunastokrotnej niższej cenie stosowanych w wymienionej branży materiałów. Stosowane materiały do produkcji elementów grzejnych nie ulegają korozji stąd mogą być używane w warunkach zagrożonych dużą wilgotnością. Wydaje się zasadnym stosowanie ich np. jako dolne wymienniki pompy ciepła albo jako elementy osłaniające przy akumulacji ciepła w gruncie czy też w instalacjach systemu osuszania powietrza w szklarni.

Wstępna ocena efektywności energetycznej przewodów grzejnych wykonanych z PP posiadających w przekroju kształt gwiazdy (wykonanej w procencie wyciskania). o nazwie rury Walczaka została przeprowadzona na Wydziale Inżynierii Produkcji i Energetyki Uniwersytetu Rolniczego w Krakowie.

Badania zrealizowano zgodnie z wytycznymi norm dotyczących warunków pomiaru urządzeń cieplnych. W pierwszym etapie badań określono jednostkową wydajność cieplną przy temperaturze otoczenia wynoszącej 15÷22 OC. Temperatura otoczenia w komorze, w której były prowadzone badania wynikała z przeznaczenia podmiotowego przewodu grzejnego. Docelowo przewód grzejny między innymi ma służyć do podgrzewania łodyg pomidora w uprawie pod osłonami. Medium grzewczym (nośnikiem ciepła) była woda o temperaturze do 56 OC. Badania wykonano w stanie ustalonym tzn. po ustabilizowaniu się wszystkich parametrów pracy w tym przypadku temperatury otoczenia (w komorze badawczej), temperatury medium grzewczego oraz natężenia przepływu. Wartości mocy stanowiącej zasilanie wyznaczono w punktach dyskretnych na podstawie realizowanych prób w przedziałach 30 min.

Badaniami objęto 12 m odcinek przedmiotowego przewodu grzejnego posiadającego pętlę umożliwiającą zmianę długości powodowaną różnicą temperatur. Badany element zawieszony był na wysokości 0,5 m i podłączony do przewodów zasilających oddalonych od siebie o 6 m. Jednostkowa pojemność wodna przewodu grzewczego wynosi 0,5 dm3, co w przeliczeniu na zastępczą średnicę o przekroju poprzecznym okrągłym odpowiada wartości średnicy wynoszącej 25,2mm. Jest to odpowiednik rury 1” w typoszeregu średnic elementów hydraulicznych.

Pomiar temperatur zarówno medium płynącego wewnątrz przedmiotowego przewodu grzejnego jak i zewnętrzną mierzono parowanymi czujnikami Pt100.

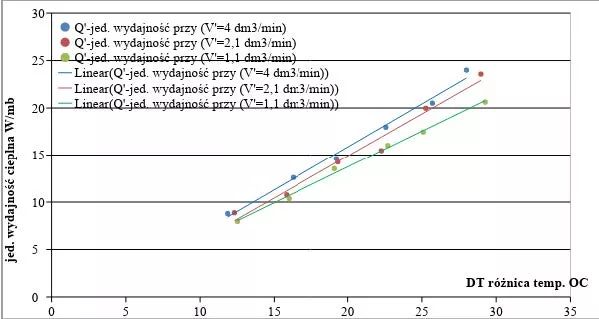

Wyniki z przeprowadzonych badań zamieszczono na wykresie (rys. 1) gdzie wydajność cieplną odniesiono do wartości jednostkowej (mocy z jednego metra bieżącego elementu grzejnego).

Badania przedmiotowego przewodu grzejnego wykonano przy trzech wartościach natężenie przepływu tj.: 4dm3/min, 2.1 dm3/min i 1,1 dm3/min co po przeliczeniu odpowiednio odpowiada średniej prędkości teoretycznej przepływu w przewodzie wynoszącej odpowiednio 13,2 cm/s, 7 cm/s i 3,6 cm/s. Dla takich wartości sporządzono charakterystyki jednostkowej wydajności cieplnej w zależności od różnicy temperatur pomiędzy medium płynącym wewnątrz przewodu, a jego otoczeniem (rys. 1). Charakterystyki te (co widoczne jest na wykresie) posiadają zależność liniową. Na wykresie tym można zauważyć że wraz ze wzrostem natężenia przepływu w niewielkim zakresie wzrasta wydajność cieplna badanych elementów. Wyraźnie widoczny jest wzrost jednostkowej wydajności cieplnej wraz z różnicą temperatur DT. Wzrost różnicy temperatur DT równy 1OC wymusza wzrosty jednostkowej wydajności cieplnej odpowiednio; o 0,912 W/mb dla natężenia przepływu 4,0 dm3/min, o 0,893 W/mb dla natężenia przepływu 2,1 dm3/min, zaś w trzecim przypadku o 0,761 W/mb dla natężenia przepływu wynoszącym 1,1 dm3/min. Na podstawie przedstawionych zależności (rys. 1) można stwierdzić iż przy natężeniu przepływu 4,0 dm3/min i przy różnicy temperatur pomiędzy czynnikiem w przewodzie grzejnym, a jego otoczeniem wynoszącym 30OC z przewodu o długości 50 m możemy uzyskać moc cieplną na poziomie 1,25 kW. Należy nadmienić iż moc ta jest uzyskana przy ogrzewaniu powietrza wykorzystując zjawiska: konwekcji, przewodzenia i promieniowania. Dla lepszego zobrazowania jednostkowej wydajności cieplnej przewodów grzejnych wykonanych z PP dokonano zestawienia tego parametru z rurą stalową również o przekroju gwiazdy, co zostało zaprezentowane na wykresie (rys. 2).

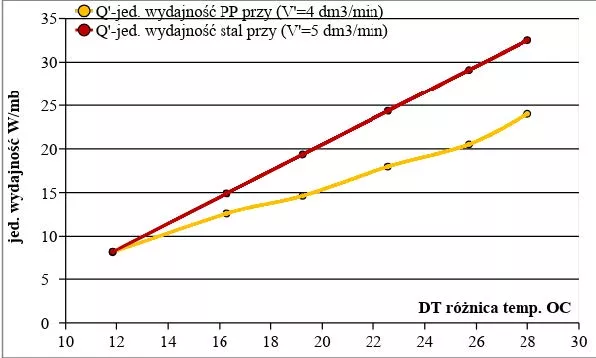

W celu oceny energetycznej innowacyjnych przewodów grzejnych wykonanych z PP dokonano porównania przedmiotowych rur z rurą stalową. Porównywane elementy grzejne posiadają przekrój gwiazdy. Porównywana rura stalowa posiada po obrysie zewnętrznym wymiar 34,5 mm co po odniesieniu do średnicy zastępczej rury okrągłej daje wartość 28 mm. Średnica zastępcza porównawczej rury jest nieznacznie większa od średncy przewodu grzejnego. Należy również nadmienić iż w trakcie badań w porównawczej rurze stalowej występował nieznacznie większy przepływ, którego wartość wynosiła 5 dm3/min. Z przedstawionych charakterystyk (rys. 2) wyniaka iż przy różnicy temperatur do 15 OC charakterystki jednostkowej wydajności cieplnej przewodu grzejnego wykonanego z PP i rury Walczaka wykonanej ze stali niewiele różnią się od siebie. Dopiero przy większych różnicach temperatur w zakresie 15 do 30 OC charakterystyki te wyrażnie od siebie odchodzą przy czym wyższe wydajności osiąga rura wykoana ze stali.

Należy pamiętać iż zalecenia te opracowano na podstawie badań przedmiotowych przewodów grzewczych w naturalnym środowisku jakim jest powietrze, gdzie zachodzą zjawiska konwekcji, przewodzenia i promieniowania.

Opinię sporządzili:

Dr hab. inż. Jarosław Knaga,

Prof. dr hab. inż. Kazimierz Rutkowski

Elementy grzejne nowej

generacji PE fi 38 mm

Wstępna ocena efektywności energetycznej przewodów grzejnych wykonanych z polietylenu posiadających w przekroju poprzecznym kształt gwiazdy (wykonanej w procencie wyciskania). Przedmiotowe przewody Walczaka zostały poddane wstępnym badaniom cieplnym na Wydziale Inżynierii Produkcji i Energetyki Uniwersytetu Rolniczego w Krakowie.

Badania zrealizowano zgodnie z wytycznymi norm dotyczących warunków pomiaru urządzeń cieplnych. W pierwszym etapie badań określono jednostkową wydajność cieplną przy temperaturze otoczenia wynoszącej 6-12 OC. Temperatura otoczenia w komorze, w której były prowadzone badania wynikała z przeznaczenia podmiotowego przewodu grzejnego. Medium grzewczym (nośnikiem ciepła) była woda o temperaturze do 52 OC. Badania wykonano w stanie ustalonym tzn. po ustabilizowaniu się wszystkich parametrów pracy w tym przypadku temperatury otoczenia (w komorze badawczej), temperatury medium grzewczego oraz natężenia przepływu. Wartości mocy stanowiącej zasilanie wyznaczono w punktach dyskretnych na podstawie realizowanych prób w przedziałach 2 godzinnych.

Badaniami objęto 12 m odcinek przedmiotowego przewodu grzejnego posiadającego pętlę umożliwiającą zmianę długości powodowaną różnicą temperatur. Badany element zawieszony był na wysokości 0,5 m i podłączony do przewodów zasilających oddalonych od siebie o 6 m. Jednostkowa pojemność wodna przewodu grzewczego wynosi 0, 39 dm3, co w przeliczeniu na zastępczą średnicę o przekroju poprzecznym okrągłym odpowiada wartości średnicy wynoszącej 22mm. Jest to odpowiednik rury 25 mm w typoszeregu średnic elementów hydraulicznych wykonanych z tworzyw sztucznych.

Pomiar temperatur zarówno medium płynącego wewnątrz przedmiotowego przewodu grzejnego jak i zewnętrzną mierzono parowanymi czujnikami Pt100.

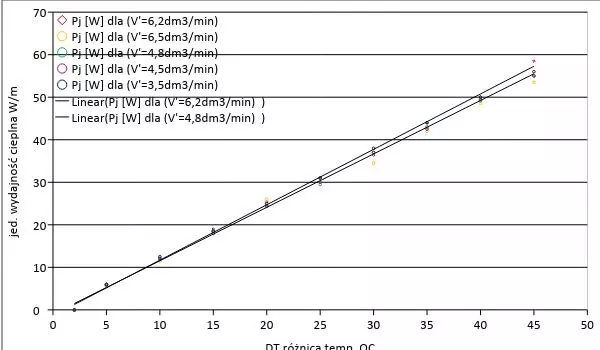

Wyniki z przeprowadzonych badań zamieszczono na wykresie (rys. 1) gdzie wydajność cieplną odniesiono do wartości jednostkowej (mocy z jednego metra bieżącego elementu grzejnego).

Badania przedmiotowego przewodu grzejnego wykonano przy pięciu wartościach natężenie przepływu w zakresie od 6,5 dm3/min do 3,5 dm3/min co po przeliczeniu odpowiednio odpowiada średniej prędkości teoretycznej przepływu w przewodzie wynoszącej odpowiednio od 30 cm/s, do 12 cm/s. Dla takich wartości sporządzono charakterystyki jednostkowej wydajności cieplnej w zależności od różnicy temperatur pomiędzy medium płynącym wewnątrz przewodu, a jego otoczeniem (rys. 1). Charakterystyki te (co widoczne jest na wykresie) posiadają zależności liniowe i praktycznie się pokrywają. Wyraźnie widoczny jest wzrost jednostkowej wydajności cieplnej wraz z różnicą temperatur DT. Wzrost różnicy temperatur DT równy 1OC wymusza wzrosty jednostkowej wydajności cieplnej odpowiednio; w zakresie od 1,3 W/mb dla natężenia przepływu 6,2 dm3/min do wartości 1,26 W/mb dla natężenia przepływu wynoszącym 4,8 dm3/min. Na podstawie przedstawionych zależności (rys. 1) można stwierdzić iż przy natężeniu przepływu w zakresie od 6,5 do 3,5 dm3/min i przy różnicy temperatur pomiędzy czynnikiem w przewodzie grzejnym, a jego otoczeniem wynoszącym 30OC z przewodu o długości 50 m możemy uzyskać moc cieplną na poziomie 1,95 kW. Należy nadmienić iż moc ta jest uzyskana przy ogrzewaniu powietrza wykorzystując zjawiska: konwekcji, przewodzenia i promieniowania. Dla lepszego zobrazowania jednostkowej wydajności cieplnej przewodów grzejnych wykonanych z polietylenu dokonano zestawienia tego parametru z rurą stalową również o przekroju gwiazdy, co zostało zaprezentowane na wykresie (rys. 2).

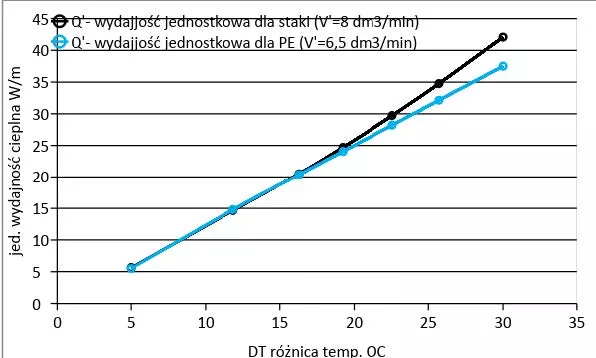

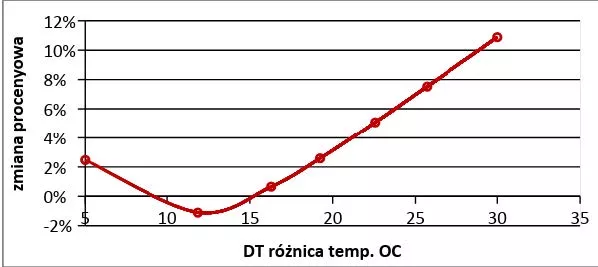

W celu oceny energetycznej innowacyjnych przewodów grzejnych wykonanych z PE dokonano porównania przedmiotowych rur z rurą stalową. Porównywane elementy grzejne posiadają przekrój gwiazdy. Porównywana rura stalowa posiada po obrysie zewnętrznym wymiar 34,5 mm co po odniesieniu do średnicy zastępczej rury okrągłej daje wartość 28 mm. Średnica zastępcza porównawczej rury jest nieznacznie większa od średncy przewodu grzejnego. Należy również nadmienić iż w trakcie badań w porównawczej rurze stalowej występował nieznacznie większy przepływ, którego wartość wynosiła 8 dm3/min. Z przedstawionych charakterystyk (rys. 2) wyniaka iż przy różnicy temperatur do 20 OC charakterystki jednostkowej wydajności cieplnej przewodu grzejnego wykonanego z PE i rury Walczaka wykonanej ze stali nie różnią się. Dopiero przy większych różnicach temperatur w zakresie 15 do 30 OC charakterystyki te nieznacznie odchodzą od siebie przy czym wyższe wydajności osiąga rura wykoana ze stali. Dla dokonania szybkiej oceny wydajności cieplnej objętych porównywaniem rur w zakresie przyjętych do badań różnic temperatur na kolejnym wykresie (rys. 3) przedstawino procentowe różnice.

Z wykresu (rys. 3) wynika iż, w zakresie różnicy temperatur DT wynoszących 5÷20 OC zmiana wydajności rur stalowych w odniesieniu do przewodów grzejnych wykonanych z PE (oba typy wykonane w technologii Walczaka) nie przekracza 2%. Dla różnic temperatur wynoszących ponad T= 20 OC można stwierdzić iż przewód grzejny wykonany z polietylenu ma wydajność grzewczą mniejszą i wraz ze wzrostem różnicy DT zmiana ta wzrasta osiągając 11% dla DT =30OC.

Przy projektowaniu urządzeń grzewczych opartych na przewodach grzejnych z polietylenu wykonanych w technologii Walczaka można posłużyć się procedurami i zaleceniami dla rur grzejnych wykonanych ze stali przy czym wymiar przewodów grzejnych wykonanych z PP należy odpowiednio procentowo powiększyć zgodnie z charakterystyką przedstawioną na wykresie (rys. 3).

Należy pamiętać iż zalecenia te opracowano na podstawie badań przedmiotowych przewodów grzewczych w naturalnym środowisku jakim jest powietrze, gdzie zachodzą zjawiska konwekcji, przewodzenia i promieniowania.

Opinię sporządzili:

Dr hab. inż. Jarosław Knaga,

Prof. dr hab. inż. Kazimierz Rutkowski